Waste is a significant source of greenhouse gas emissions. Reducing the amount of green waste and recyclable materials entering landfills reduces methane and other greenhouse gas emissions.

![]()

BACKGROUND

In 2020, the California Workforce Development Board, through its High Road Training Partnership initiative, offered funding to organizations that could help tackle climate change, improve job quality and promote equity for disadvantaged populations. Recognized as leaders in workforce development and sustainability in the fresh produce industry, Equitable Food Initiative (EFI) and Measure to Improve (MTI) partnered for the first time on a pilot program at three California agricultural facilities, bringing an innovative approach to building organizational capacity, improving waste management practices and reducing greenhouse gas emissions.

PROGRAM GOALS

- Provide fresh produce companies and employees with the knowledge and skills necessary to develop waste reduction programs and a culture of sustainability.

- l Reduce the emission of greenhouse gases that contribute to climate change by keeping waste materials out of the landfill.

Pilot Participants

Andrew & Williamson Fresh Produce/GoodFarms Buenaventura Ranch, an open field strawberry farm, Santa Maria, California

Misionero leafy greens packing and processing facility, Gonzales, California

Windset Farms® tomatoes and cucumbers greenhouse operation, Santa Maria, California

This project was a natural fit for GoodFarms. Investing in sustainability is a core value for the company because it simultaneously improves the quality of our products and the quality of lives by protecting our ecosystem and preserving natural resources

for future generations.”

AMALIA ZIMMERMAN-LOMMEL, DIRECTOR OF SOCIAL

RESPONSIBILITY, GOODFARMS

PROCESS

ESTABLISHING GREEN TEAMS

EFI and MTI have experience addressing organization-level challenges in the fresh produce industry by using diverse teams. Following an approach that brought strengths from the MTI model of developing a Green Team of representatives from multiple departments and the EFI model of creating worker-management collaborative teams, each pilot site established a Green Team with diverse membership customized to meet its organization’s internal needs. Teams included 12 to 20 members from upper-level management, accounting and data analysis, human resources and training, operations management, field/plant supervision, facilities maintenance and frontline planters, pruners, harvesters and janitors.

Implementing Produce & Reduce has helped us increase efficiency and generate long-term business value by fostering a culture of sustainability and responsible resource management. By investing in our workforce through such training programs, we are creating a lasting positive impact on the bottom line and the environment.”

JOHNNY ARRIAGA, SENIOR PLANT OPERATIONS MANAGER,

MISIONERO

Implementing Produce & Reduce has helped us increase efficiency and generate long-term business value by fostering a culture of sustainability and responsible resource management. By investing in our workforce through such training programs, we are creating a lasting positive impact on the bottom line and the environment.”

JOHNNY ARRIAGA, SENIOR PLANT OPERATIONS MANAGER,

MISIONERO

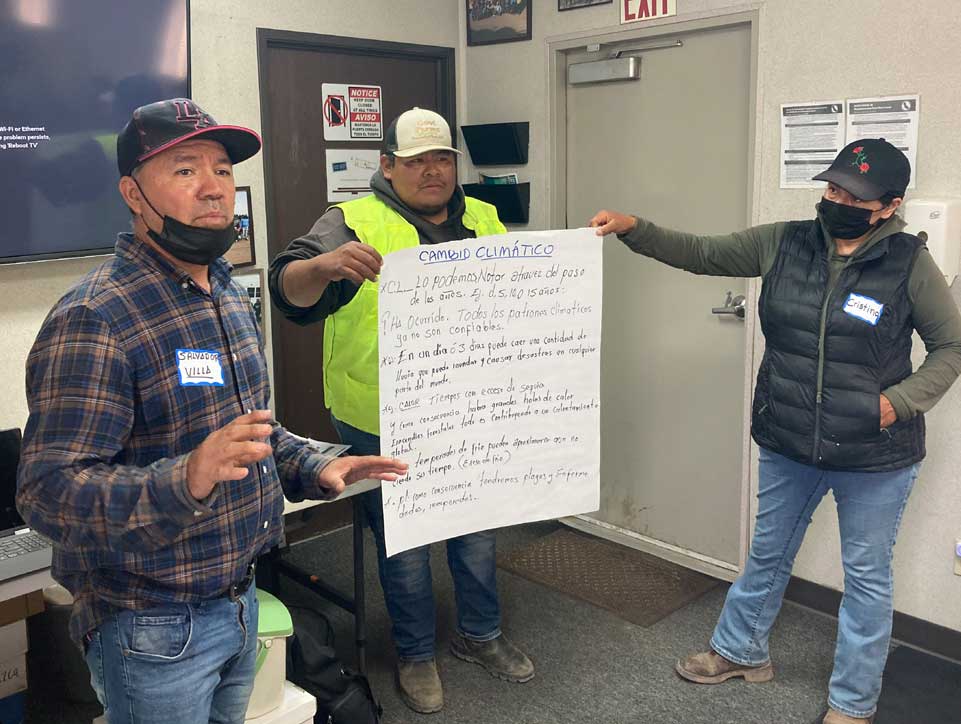

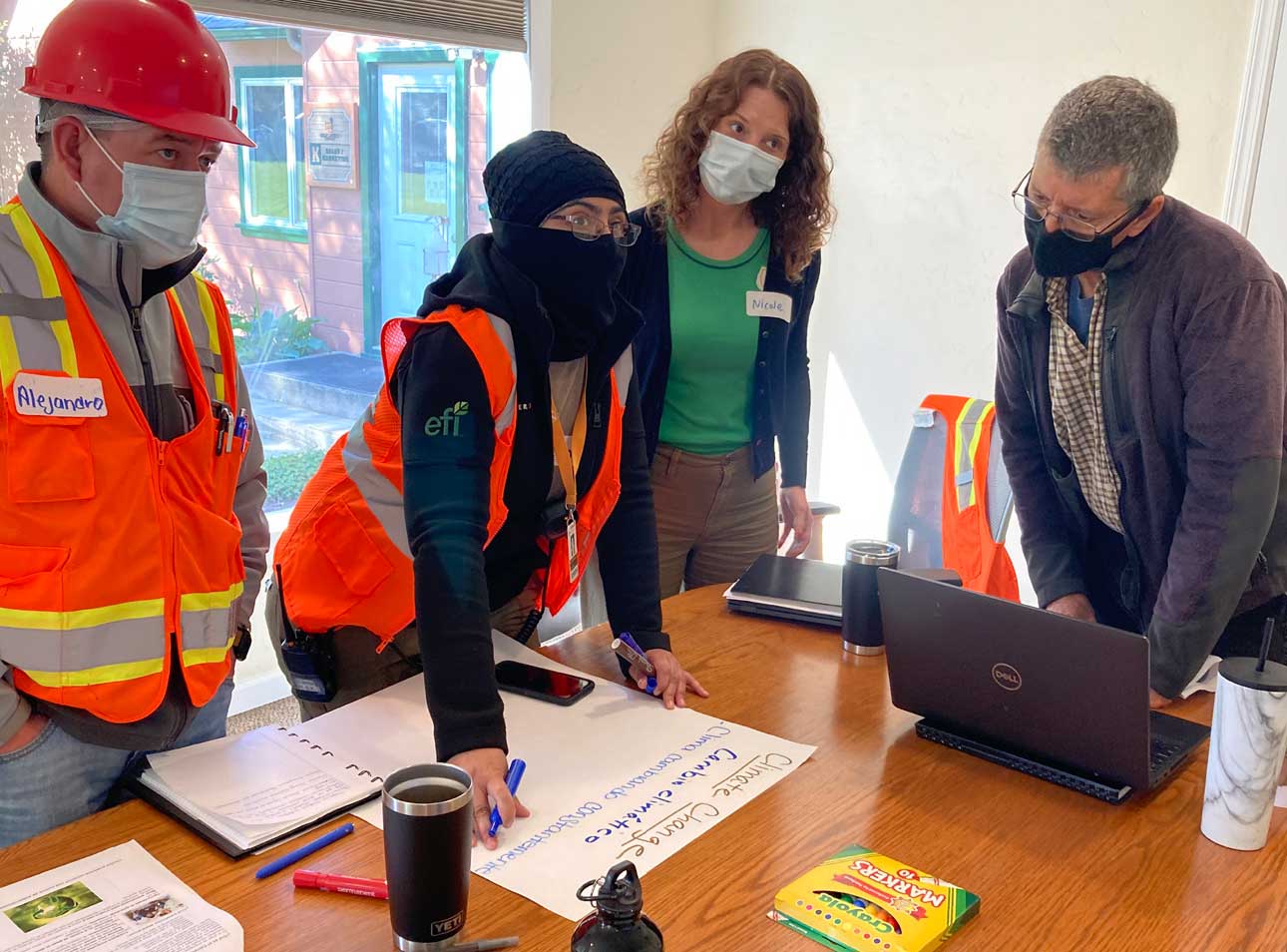

TRAINING AND IMPLEMENTATION

EFI and MTI led the Green Team members at each pilot site through training sessions and hands-on activities to build their capacity to develop and implement a waste reduction plan. Teams were encouraged to identify waste-related problems or opportunities and design solutions to fit their organizations as they progressed through the training and activities.

Green Teams conducted their own physical waste audits, sorting and weighing the contents of an entire landfill container. Based on this data, teams then determined which materials could be reduced, reused, recycled, composted or otherwise diverted from the landfill, and they prioritized actions in their waste reduction plan.

Pilot Program Training Topics

![]() General background on sustainability, climate change, greenhouse gas emissions and waste reduction

General background on sustainability, climate change, greenhouse gas emissions and waste reduction

![]() Waste audits to assess material streams and opportunities for waste reduction

Waste audits to assess material streams and opportunities for waste reduction

![]() Waste reduction plan development and implementation

Waste reduction plan development and implementation

![]() Data collection and analysis of the volume and cost of waste streams over time

Data collection and analysis of the volume and cost of waste streams over time

![]() Communication of the goals and actions of the waste reduction plan to the workforce

Communication of the goals and actions of the waste reduction plan to the workforce

![]() Use of data and problem solving for continuous improvement

Use of data and problem solving for continuous improvement

TIMELINE

2021

- Produce & Reduce Pilot Program Launches

- l Program Training Begins

- l Green Teams Established

- l Baseline Materials Management Systems Assessed

- l Initial Waste Audit Conducted

2022

- l Waste Reduction Plans Developed

- l Waste Reduction Plans Implemented

- l Program Training and Support Continues

- l Data Tracking Activities Progress

- l Second Waste Audit Conducted

2023

- Data Analysis Completed

- l Training on EPA WARM Tool Provided (to estimate reduction in greenhouse gas emissions)

- l Waste Reduction Plans Updated

- l Produce & Reduce Pilot Program Complete

- l Green Teams Continue to Improve Waste Reduction

- Plans and Program at Each Company

BY THE NUMBERS

50

Number of people trained directly by EFI and MT

2557

Estimated number of indirect trainees

144+

new tons

Total volume of materials kept out of landfill

435+

MTCO2e

Total reduction in greenhouse gas emissions (equivalent to 1,080,454+ miles driven by an average gasoline powered passenger vehicle)

CULTURE OF SUSTAINABILITY SUPPORTS CONTINUOUS IMPROVEMENT IN WASTE REDUCTION

The Produce & Reduce pilot program approach was developed around the idea that the success of an organization wide waste reduction program would depend on the engagement of the entire workforce to effectively implement changes.

The three waste reduction plans developed through this program reflected the diversity of challenges and perspectives unique to each organization; however, all plans shared the need for employee engagement at all levels of the workforce.

Program participants agree that the Green Team model provided the organizational structure and communication systems needed to support a shift toward a culture of sustainability, where employees are empowered to think critically about waste reduction and understand their role in maintaining a system that leads to less waste, reduced costs and lower greenhouse gas emissions.

The three pilot participants continue to track and improve their materials use programs and plan to conduct annual waste audits to gauge progress and identify new opportunities.

We have saved money and generated funds through increased recycling and waste reduction programs. Every single company should get started, because there are financial savings along with positive environmental impacts.”

JEFF MADU, VICE PRESIDENT OF SALES,

WINDSET FARMS

SPECIAL THANKS

Support from the California Workforce Development Board allowed EFI and MTI to join forces with forward-thinking companies that were willing to invest significant time and resources to strengthen their waste reduction programs. Through this pilot, the companies discovered passionate sustainability champions within their workforce who can be developed as leaders.

We learned that having a strong EFI team and a culture of labor-management collaboration gives companies an excellent foundation for sustainability initiatives like this one. Engaging the entire workforce in sustainability efforts can be a powerful way to create organization wide change and motivate people to take action to reduce our environmental impacts both in the workplace and at home. This is what it looks like to transform hearts and minds!”

LILIAN AUTLER, ORGANIZATIONAL & WORKFORCE DEVELOPMENT MANAGER, EFI

It was rewarding to see how far-reaching this program was. Members from the participating organizations prided themselves on sharing and educating their neighbors, families, and friends on placing materials in the proper containers. Everyone was doing their part to reduce the negative impacts food loss and waste has on the environment. This waste reduction program was a perfect example of incorporating all three pillars of sustainability – people, planet, and profitability – and how to approach sustainability initiatives moving forward. It starts with assembling a Green Team, data collection, and goal setting, then follows the training and internal and external communications.”

NIKKI COSSIO, CEO & FOUNDER, MEASURE TO IMPROVE, LLC

200 Massachusetts Avenue, NW, Suite 700,

Washington, DC 20001

202.730.6672

equitablefood.org

820 Park Row #333

Salinas, CA 93901-2406

831.594.7972

measuretoimprovellc.com

The way of thinking has definitely changed for the workers. We didn’t just implement Produce & Reduce at work but also in our daily lives. Workers are sharing the message with their families, and we are creating consciousness widely.”

LUZ CRISTINA RODRIGUEZ, CREW LEADER, GOODFARMS